PARTNERSHIPS

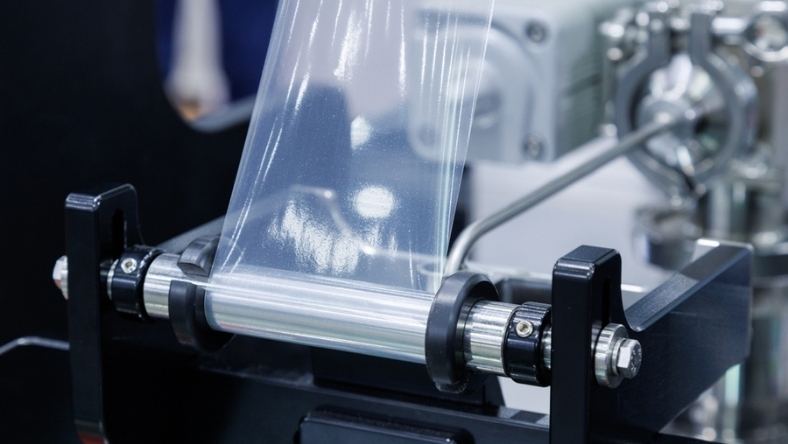

Packaging Alliance Races to Recycle Flexible Films

Emerald Packaging joins a recycling coalition as California regulations push the industry to rapidly scale flexible film recovery infrastructure

3 Feb 2026

A weak link in America’s recycling system is finally being pulled tight. Flexible plastic films, used for everything from salad bags to detergent refills, have long been hard to collect and process. Now an industry alliance, nudged by regulation, is trying to make them behave more like conventional packaging.

Emerald Packaging, a supplier of flexible films, has become the first manufacturer to join the US Flexible Film Initiative, a coalition set up to expand recycling capacity for such materials. Until now the group has been led mainly by big consumer brands, including Mars and PepsiCo, which depend heavily on flexible packaging and face mounting pressure to clean up their waste.

For years the industry focused on making packaging thinner or easier to recycle in theory. In practice, films slipped through the cracks. Most municipal systems cannot sort them, and many recycling plants lack the equipment to process them. Recycling rates stayed low, even as companies boasted of smarter designs.

The initiative aims to tackle that gap directly. By pooling funding, data and technical know how, it plans to upgrade sorting lines and processing plants, starting in California. That is no accident. The state’s SB 54 law requires all single use packaging and plastic foodware to be recyclable or compostable by 2032. The rule does not merely encourage better design; it demands functioning systems to handle the waste.

Emerald Packaging’s decision reflects a growing acceptance of that logic. As a supplier, it sits between designers and recyclers, and sees where good intentions fail. Its move suggests that recyclability cannot be delivered by brand promises alone. Manufacturers, too, must help build the machinery that makes recycling possible.

There are clear incentives. Better infrastructure would help firms comply with California’s rules and support higher use of recycled content, which many brands have pledged. It may also spread costs more evenly across the value chain, rather than leaving them with municipalities.

The obstacles are substantial. Modernising recycling plants is expensive, coordination is hard and smaller firms may struggle to keep up. Yet the direction of travel is plain. As rules tighten, collaboration is becoming less optional. If the effort works, flexible films may at last shift from a symbol of recycling’s limits to a test case for fixing them.

Latest News

12 Feb 2026

PFAS Exit Marks Turning Point for Food Packaging11 Feb 2026

Walmart Turns Every Pallet Into a Data Point10 Feb 2026

Industry Alliance Targets Gaps in Plastic Film Recycling9 Feb 2026

Is Smart Packaging Moving Beyond Single-Use?

Related News

REGULATORY

12 Feb 2026

PFAS Exit Marks Turning Point for Food Packaging

INNOVATION

11 Feb 2026

Walmart Turns Every Pallet Into a Data Point

PARTNERSHIPS

10 Feb 2026

Industry Alliance Targets Gaps in Plastic Film Recycling

SUBSCRIBE FOR UPDATES

By submitting, you agree to receive email communications from the event organizers, including upcoming promotions and discounted tickets, news, and access to related events.